A weeklong series of ideas for improving urban life.

In January of this year, a mansion rose in Shanghai. But rather than being built by cranes and construction workers, the six-story structure was 3-D-printed — assembled layer upon layer by a nozzle extruding a mush “ink” made of construction waste products like concrete, fiberglass, and sand. Fabricated by the Chinese engineering company WinSun, the 3-D-printed mansion’s facade is oddly smooth and its interiors featureless, like an empty dollhouse. But the technology that created it could before long reshape entire cities.

As large-scale 3-D printing evolves, buildings created by the process will be faster, cheaper, and more architecturally interesting than traditional structures. They can be built where they stand, and customizing a new design is as easy as altering a computer model. The process “allows us to digitally fabricate new material systems and building components with varied properties of density, translucency, elasticity, and much more,” says Areti Markopoulou, a professor at Barcelona’s Institute of Advanced Architecture. Imagine ovular windows as easily built as brick, or curved facades without the leakage problems that plague Frank Gehry.

At a moment when the world’s leaders are gathered in Paris trying to find a way to cut greenhouse emissions and avoid cooking the planet, there is another remarkable upside: A 3-D-printed building is much greener than a traditionally built one. WinSun estimates that its printed structures require 60 percent less material. “The duration of construction is not very long and people don’t drive back and forth to the work site,” says Dr. Behrokh Khoshnevis, a professor at USC and leading innovator in large-scale 3-D printing.

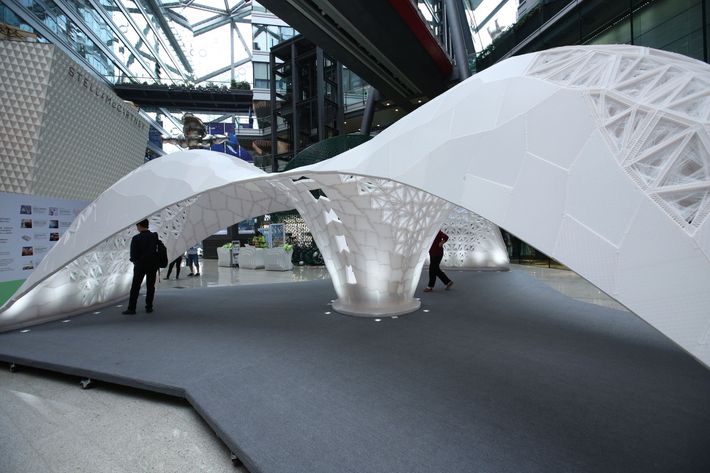

A handful of other printer-architecture projects have already been completed around the world. A 26-foot-long, 10-foot-tall pavilion, called Vulcan, was printed and unveiled in Beijing earlier this year, its modular structure and threaded texture inspired by silk cocoons. Architect Yu Lei used digital fabrication throughout the design and construction process. “This development will increasingly blur the boundaries between technology and art,” he explained at the project’s launch. In Amsterdam, DUS Architects’ Canal House is an ongoing pop-up project with a series of smaller-scale experiments working toward printing a full-size traditional Dutch home.

Using its unique 23-foot-high rig, WinSun is also partnering with the Egyptian government to create cheap one-story homes in the desert. Another global collaborative project will result in curvilinear office buildings in front of Dubai’s aptly named Museum of the Future. While the Vulcan pavilion pushes the boundaries of architecture, WinSun’s work is more familiar — it’s as recognizable as a freshly built condo (and there’s no reason those can’t be 3-D-printed soon).

Once the technology starts to get traction, buildings will increasingly be reshaped around the capabilities of a 3-D printer. That means architectural structures that can function more like bone: thicker in some areas, thinner in others, but all made of the same stuff. It’s this flexibility that allows 3-D-printed architecture to take on any shape the designer imagines, even the alien aesthetics of a starchitect like Zaha Hadid.

Further into future, there will be whole 3-D-printed cities — flexible places, where buildings and infrastructure are constantly and easily modified (which is to say, reprinted). The technology makes the urban canvas more adaptable and modular. New homes can be built quickly and cheaply when the need arises — in, for example, the case of an emergency influx of refugees.

It’s not all Utopian, however. Building in place might be sustainable, but it’s also limited to the size of the printer’s framework, the architects note. And to move forward on a bigger scale, architects need innovations like 3-D-printed reinforced concrete, a way to print solid slabs, and a more scalable process “both vertically and horizontally,” says Adam Kushner, president of D Shape Enterprises, a 3-D-printed architecture firm. The potentials of large-scale 3-D printing are also coming to light amid a general sense of disappointment over the state of consumer 3-D printing, with industry leader Makerbot’s valuation falling by $140 million this year.

While urban architecture hasn’t been remixed quite yet, 3-D printers are already remaking how architects think about buildings. “You don’t have limitations, with respect to geometry,” Khoshnevis says. 3-D printing lets designers “see a product of your imagination take on physical form,” says Neri Oxman, creator of the Mediated Matter group at MIT’s Media Lab. Architects have long drawn buildings, but this is the first time those drawings can instantly become reality.